|

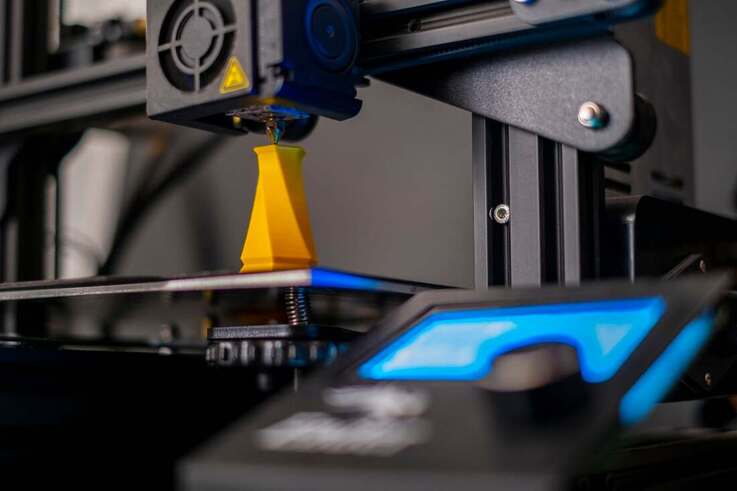

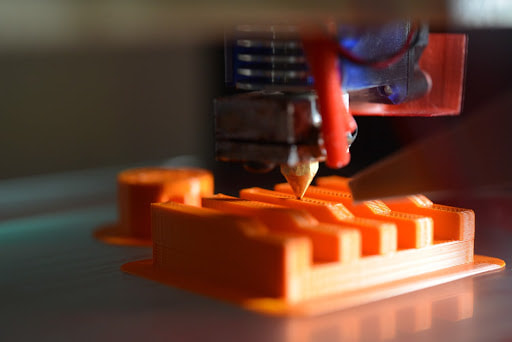

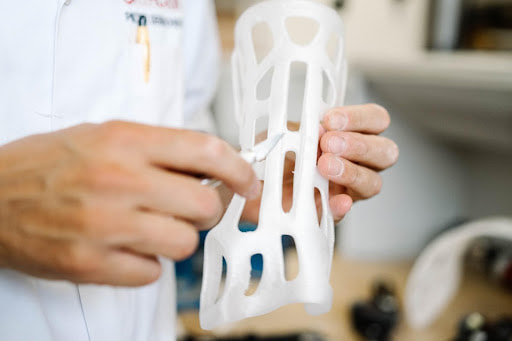

3/18/2023 0 Comments The science behind 3D printingBy Celine Nugroho Edited by Kendra Loedige In 1945, author Murray Leinster dreamed of a wondrous machine in his sci-fi short story, Things Pass By. He wrote that the machine could manufacture physical objects based on a drawing. About 40 years later, Leinster’s machine was brought to life through the first recorded instance of 3D printing. A 3D printer at work (Credit: Osman Talha on Unsplash) 3D printing, otherwise known as additive manufacturing, is the process of creating three-dimensional solid objects from digital models. In most iterations, the procedure starts out with a file containing the 3D model design of an object. The file is then processed by the 3D printer. Afterwards, the printer initiates an additive process where it builds the object layer by layer. These layers are placed sequentially until the desired object is created. Types of 3D printing There are several different types of 3D printing. One of the most common types of 3D printing is fused deposition modelling (FDM). FDM printers heavily involve the use of thermoplastics, or polymers that soften when exposed to heat and solidify when cooled. Thermoplastics such as acrylonitrile butadiene styrene and polylactic acid are squeezed out through a heated nozzle into a build platform. As the material melts, it is used to construct a material layer by being placed in predetermined areas to cool. When the layer is finished, the platform moves downwards in anticipation of the following layers. Fused deposition modelling (Credit: Gavin Allanwood on Unsplash) Another widely used 3D printing process is stereolithography (SLA). This technique was the world’s first 3D printing technology. Its popularity remains steadfast to this day due to its ability to generate highly accurate objects with smooth surface finishes. SLA printers utilise a process called photopolymerisation, a reaction that converts a liquid or gel monomer into a solid polymer upon induction by light. These printers are equipped with computer-controlled laser beams that move around to cure liquid resin on a build platform. After a layer is produced on the resin surface, the platform descends to allow application of the next resin layer. Depending on certain factors like chosen printing type, output size, and intended quality, 3D printing an object can take as short as a few minutes or as long as several days. 3D printing across various industries Although 3D printing was invented in the 1980s, it wasn’t until the 2000s that its popularity began to skyrocket. Around this time, 3D printers and its associated tools were made commercially available. People could design their own models on their personal computer and 3D print from home. Nowadays, 3D printing is applied in many fascinating avenues. One of its most prominent uses is in the medical industry, where 3D printers are employed to manufacture medical devices like prosthetic limbs and support braces. In fact, scientists are now researching organ bioprinting, a type of 3D printing that assembles layers of cells and other biomaterials to produce artificial organs. All of this cements 3D printing’s revolutionary mark on healthcare, and promises how the technology will help save many more lives. Another application of 3D printing is in the construction industry. Advancements in 3D printing have allowed for entire building structures to be established through this method. This is because 3D construction printing allows for more design flexibility, stronger productivity and higher cost efficiency. An impressive example is a 3-story villa in Saudi Arabia, which was built with 3D printable concrete made from local materials. With a staggering height of 9.9m (32 feet), the building has been dubbed “the tallest on-site 3D printed building in the world." This 3D printed clay-mixture house built in 2021 by WASP in Italy can be printed in 200 hours Credit details: https://commons.wikimedia.org/w/index.php?curid=105630312 Full video: https://www.youtube.com/watch?v=w9sXqxccRPM&ab_channel=3DWASP CC BY 2.5 3D printing can even be used to “print” food. In 2011, students and scientists at Cornell University equipped a 3D printer with edible ink. The ink was made out of any food with a liquid consistency that could fit through a syringe. It was then used to print food in different shapes and textures. This opens the door for many new innovations in the gastronomic scene, as chefs can now customise the visual appearance of their dishes to their heart’s desire. While 3D printing has come a long way since being a figment of sci-fi imagination, there is certainly much more room for innovation. There are limitless possibilities as to how 3D printing can further revolutionise the way products are designed, created, and produced. Who knows, someday we might just turn to 3D printing everything in our lives! What would you use a 3D printer for? Let us know in the comments or @Scientista_Talk!

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

LIFESTYLE BLOGRead our lifestyle advice, written exclusively for pre-professional women in science and engineering. From advice about fashion, work and family balance, self, wellness, and money, we've got you covered! |

The Scientista Foundation, Inc. All Rights Reserved © 2011-2021 | Based in NY | [email protected]

The Network for Pre-Professional Women in Science and Engineering

The Scientista Foundation is a registered 501(c)(3) -- Donate!

The Network for Pre-Professional Women in Science and Engineering

The Scientista Foundation is a registered 501(c)(3) -- Donate!